Rail tracks, a linchpin of railway transportation, are under constant stress from train loads. As they age, diverse surface damages emerge, posing significant threats to both the lifespan of the rails and the safety of railway operations. Let's explore these potential issues in detail.

· Side Wear: Predominantly found on the outer rails of curves, side wear results from the pressure and friction exerted by train wheels. This not only reduces the lateral dimension of the rail head but also disrupts the wheel - rail interaction, potentially compromising rail strength and train stability.

· Vertical Wear: Occurring due to the vertical forces during wheel rolling, vertical wear flattens the rail head. This, in turn, diminishes the rail's load - bearing capacity and its ability to resist fatigue.

· Fish - scale - like Wear: Characterized by a fish - scale pattern, this type of wear is a result of repeated train loads causing fatigue cracks to spread. It not only heightens wheel - rail noise but also accelerates the wear of both wheels and rails, with severe cases leading to rail fractures.

· Head Checks: Typically forming within the rail head, head checks are small cracks that develop in stress - concentrated areas due to repeated wheel loading. If undetected, these can grow and cause sudden rail failures, endangering train travel.

· Transverse Cracks: Running perpendicular to the rail's axis, transverse cracks are often caused by internal defects or fatigue stress. Their rapid spread can lead to rail fractures, posing a major risk to train safety.

· Longitudinal Cracks: Parallel to the rail's axis, longitudinal cracks stem from manufacturing flaws or excessive longitudinal forces. They weaken the rail and may evolve into more dangerous transverse cracks.

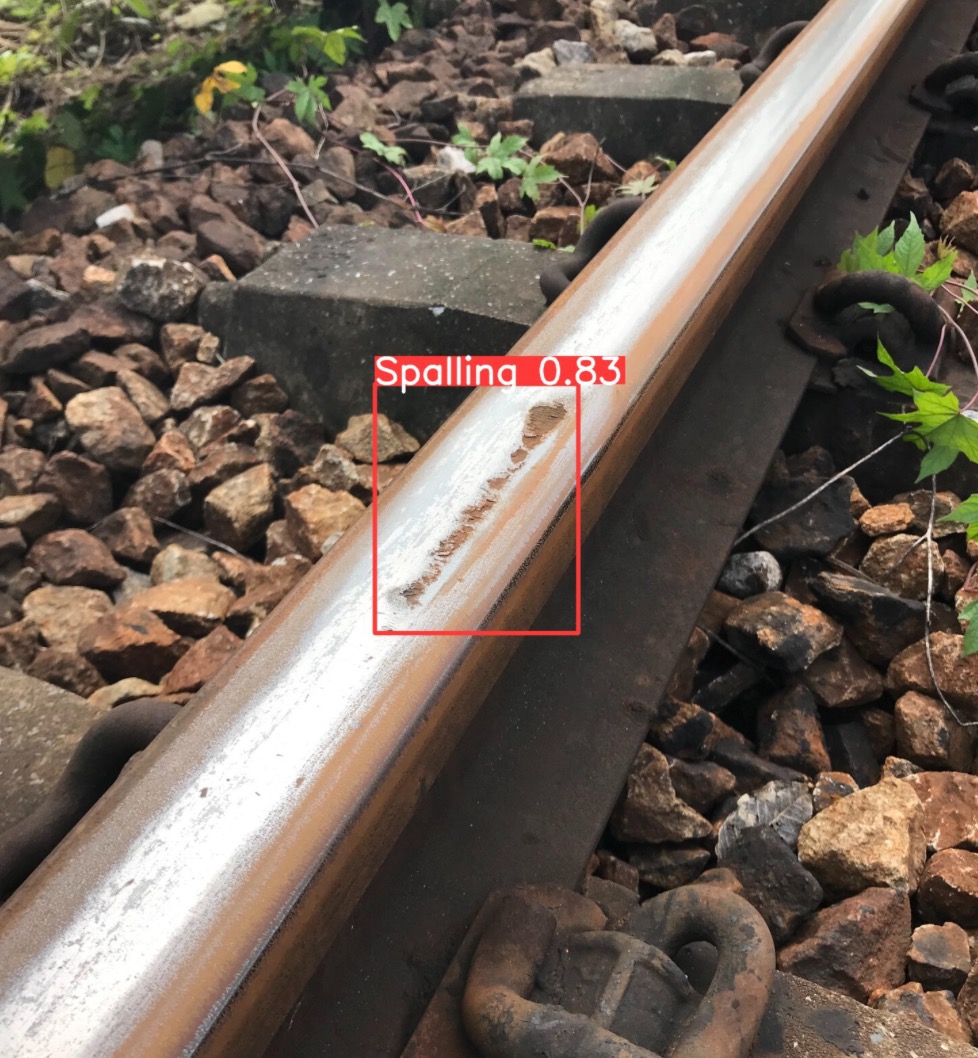

Spalling occurs when small metal fragments break away from the rail surface under wheel pressure, often due to material fatigue, wear, or internal flaws. This not only mars the rail's surface but also affects train ride quality and accelerates further damage.

Exposed to the elements, rails are prone to corrosion from air, moisture, and chemicals. Corrosion creates rust spots and pits, reducing the rail's surface quality and strength, and exacerbating wear and fatigue, especially in harsh environments.

Understanding these rail surface damages and enhancing inspection and maintenance efforts are crucial for ensuring safe and efficient railway transportation, allowing trains to operate smoothly and securely.

Copyright © Wuhan Linkage Track Equipment Co., Ltd All Rights Reserved.